Smarter Building Starts Here

The construction industry is changing—and fast. With rising material costs, labor shortages, and growing environmental concerns, builders and developers are looking for better ways to construct buildings that are faster, safer, and more efficient. That’s where prefabricated construction, especially pre-engineered metal buildings (PEMBs), is taking center stage.

Once considered a niche or temporary solution, prefab building has evolved into a highly scalable, technology-driven approach that’s reshaping how we build everything from warehouses and retail spaces to schools and storage facilities.

So, what does the future hold for this rapidly growing sector? Let’s take a look at the trends, innovations, and opportunities defining the next generation of prefab construction.

Prefabricated Construction at a Glance

Prefabricated construction refers to the process of building key structural components off-site in a controlled environment, then transporting those components to the job site for quick assembly.

This method offers major advantages:

- Shorter construction timelines

- Improved safety conditions

- Higher quality control

- Reduced material waste

- Lower long-term costs

PEMBs are a leading example—where every piece of steel is precision-fabricated to fit together with minimal error, resulting in a faster, more reliable construction process.

Trend #1: Off-Site Is Becoming the New Standard

As job site constraints increase and cities become denser, off-site construction is becoming more than just a smart option—it’s becoming essential.

Prefabrication reduces on-site traffic, noise, and waste while allowing projects to continue despite weather delays. With more construction moving toward modular and kit-based methods, the industry is leaning heavily into off-site production as a long-term solution.

Trend #2: Tech-Driven Design and Automation

Modern prefab buildings are no longer designed on paper. Today, developers are using:

- Building Information Modeling (BIM) for 3D planning

- AI-assisted layout optimization

- Robotic welding and cutting during manufacturing

- Digital twins to monitor building performance post-completion

These innovations help reduce errors, predict material needs, and optimize every square inch of a building—resulting in smarter designs with fewer surprises.

Trend #3: Sustainability Is a Core Focus

Environmental responsibility is no longer a “nice-to-have”—it’s a necessity. Prefabricated metal buildings support sustainability by:

- Using recycled steel

- Generating less on-site waste

- Allowing easy integration of solar panels, efficient HVAC systems, and LED lighting

- Promoting long-term durability to avoid frequent rebuilds

As more cities adopt green building codes, prefab construction is becoming a key path to meeting those goals quickly and affordably.

Trend #4: Faster Timelines Are Reshaping Project Planning

In an industry where time is money, PEMBs are allowing companies to meet tighter deadlines and get to market faster. Developers can often shave weeks or even months off a typical build.

Faster builds mean quicker ROI, especially for storage, warehousing, and commercial operations where getting online fast is essential to profitability.

Trend #5: Customization Is More Advanced Than Ever

Gone are the days when prefab buildings looked like cookie-cutter boxes. Today’s pre-engineered buildings can include:

- Multiple rooflines and architectural elements

- High-end exterior finishes

- Skylights and window systems

- Office buildouts and mixed-use space

- Custom interior zoning for HVAC and lighting

This flexibility allows businesses to meet strict brand guidelines, create attractive storefronts, or design complex operational layouts—all while enjoying the efficiency of prefab.

Trend #6: Hybrid Projects Are on the Rise

Not every project is 100% prefabricated—and that’s okay. More architects are using hybrid designs that combine prefab steel with concrete, glass, or wood accents for a modern, mixed-material look.

These projects benefit from steel’s strength and speed while still allowing for creative freedom. It’s the best of both worlds.

Trend #7: Labor Shortages Are Pushing Prefab Growth

With fewer skilled workers available, prefab construction helps fill the gap. Off-site manufacturing requires fewer on-site trades, and the work can be completed with more consistency and less risk.

This not only reduces the chance of error but also keeps construction schedules more predictable.

Trend #8: Prefab Is Expanding into New Markets

While PEMBs have long been used for warehouses and storage, they’re now being adapted for:

- Medical clinics and healthcare buildings

- Educational campuses and gymnasiums

- Restaurants and quick-serve retail

- Government and utility infrastructure

The adaptability of steel and prefab systems is opening doors across industries, especially where durability and speed are top priorities.

The Future Is Pre-Engineered

As innovation continues to shape the construction world, prefab building—particularly pre-engineered metal construction—is becoming the go-to solution for fast, affordable, and sustainable development.

With every project, the benefits grow clearer:

- Greater speed

- Smarter resource use

- Long-term performance

- Lower environmental impact

Builders, developers, and business owners who embrace this trend now are positioning themselves ahead of the curve.

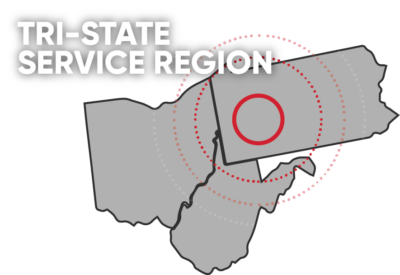

Build What’s Next with Red Direct

Prefabricated steel construction is fast, efficient, and built to last—giving you the freedom to innovate, expand, and succeed without the usual delays or headaches. With Red Direct’s PEMB solutions, you get smarter building today and a future-ready structure tomorrow.